Eduardo Chillida, the Basque artist, installed one of his best-known series of sculptures on the breakwater of Donostia and called it “The Comb of the Wind.” And there is something of that in the wind turbines that are beginning to populate the coastal waters of many countries. Between 2020 and 2021, the energy capacity of these “wind combs” will almost double, reaching 48.2 GW. In turn, floating offshore wind has begun to represent a significant part of the total installed wind farm on a global scale.

In this article, you will find the following contents:

What is floating offshore wind, and how does it work?

The traditional approach to installing offshore wind farms has been to move onshore wind turbine structures to shallow coastal waters. One of the reasons is that offshore winds are more stable and intense, as they do not face obstacles as onshore, such as mountains or forested areas.

One of the challenges of offshore wind power is to fix the structures of these wind turbines to the seabed and make them robust enough to withstand the onslaught of waves. The fact that it is necessary to install such a support limits its possibilities to the continental shelf closest to land in shallow waters.

Floating platforms, also known as Floating Offshore Wind Platforms (FOWP), overcome some of these pitfalls by using floating structures connected to the platform by steel or other cables. These cables keep the platform stationary while providing some mobility in very strong waves.

Advantages of floating offshore wind turbines

As can be seen, the floating offshore wind energy approach offers numerous advantages, including the following:

- It can be installed in deep waters

- Can be easily moved in case of need

- Reduced environmental impact on the seabed

- Lower installation cost

- It harnesses stronger winds

- Reduced visual impact by being able to be installed at a greater distance from the coastline

Types of floating offshore wind

To a large extent, the wind turbines used on the platforms tend to share similar characteristics, except for some developments that use two-bladed windmills. The main difference is underwater, in the type of floating platforms used. In this regard, the following variants could be mentioned:

- Spar buoy. This platform uses a cylindrical base that offers a simple and efficient design, with the weight applied at the lower end. It requires more than one hundred meters of depth to operate properly.

- Barge or pontoon model. Unlike the Spar design, the platform is more like a ship in terms of length and width.

- Semi-submersible base. It uses several semi-submersible cylinders connected utilizing beams.

- TLP model (Tension Leg Platform). It is based on a central column and arms connected to the tensioners to ensure stability.

Wind pyramids: an innovative approach

One of the few models in which the most marked divergences are manifested on the surface is the proposal of the French company Eolink. This is because the wind turbine is conceived from the outset as a model intended for floating offshore wind, and its entire design leverages the particularities of the environment.

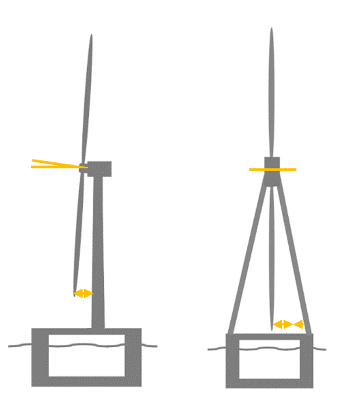

On land, wind turbines use a design known as a “nacelle.” That is, with an ovoid body like aircraft engines. This design allows a heavy structure to behave like a head that turns and “faces” the direction of the wind. Mobility at sea, on the other hand, is very different. And that is the first differentiating factor of the “pyramidal” turbines.

The model proposed by Eolink dispenses with the nacelle and is inserted into a pyramidal structure composed of four masts. Here it is the entire platform that rotates, instead of the wind turbine head. A nacelle turbine has weight limitations and even more so at sea, where waves and strong winds expose it to a lot of wear and tear. Think of a very heavy “head” with a thin neck to understand this. On the other hand, the combined mast structure can hold much larger turbines.

Another way to reduce wear and tear on the structure of a wind turbine is to use flexible blades. The problem with the nacelle model is that the proximity of the main mast prevents the use of blades that are too long and flexible, as they could impact it.

According to its developers, the “pyramid” of masts reduces the risk of impact and allows the use of longer and more flexible blades, resulting in higher energy efficiency. In addition, this structure distributes weight better and improves strength.

Coupled with a new floating platform design with a buoy at a depth of 20 meters, the new wind turbines could produce 20 MW per unit with an efficiency 20-25 % higher than current reference solutions.

This innovative floating offshore wind approach is still in the prototype phase, but the manufacturer plans to install a demonstration wind turbine with a capacity of 5 MW in the near future.

Sources